HEADFOAM

Shock Absorbing Structures For Sports Helmet

Head Protective Equipment Fabricated With Additive Manufacturing

Project: Design and test of shock-absorbing structures produced by AM to be applied to helmets used as PPE (Personal Protective Equipment) in sports as climbing, biking, skating, etc.

Innovation: Use of an impact-absorbing structure designed specifically for AM production.

Challenge: We believe that an inner structure of a safety helmet designed with a shock-absorbing lattice structure and produced by AM would make a better helmet.

Application: The solution PPE helmet can be used in outdoors sports as climbing or biking or skating..

Activities:

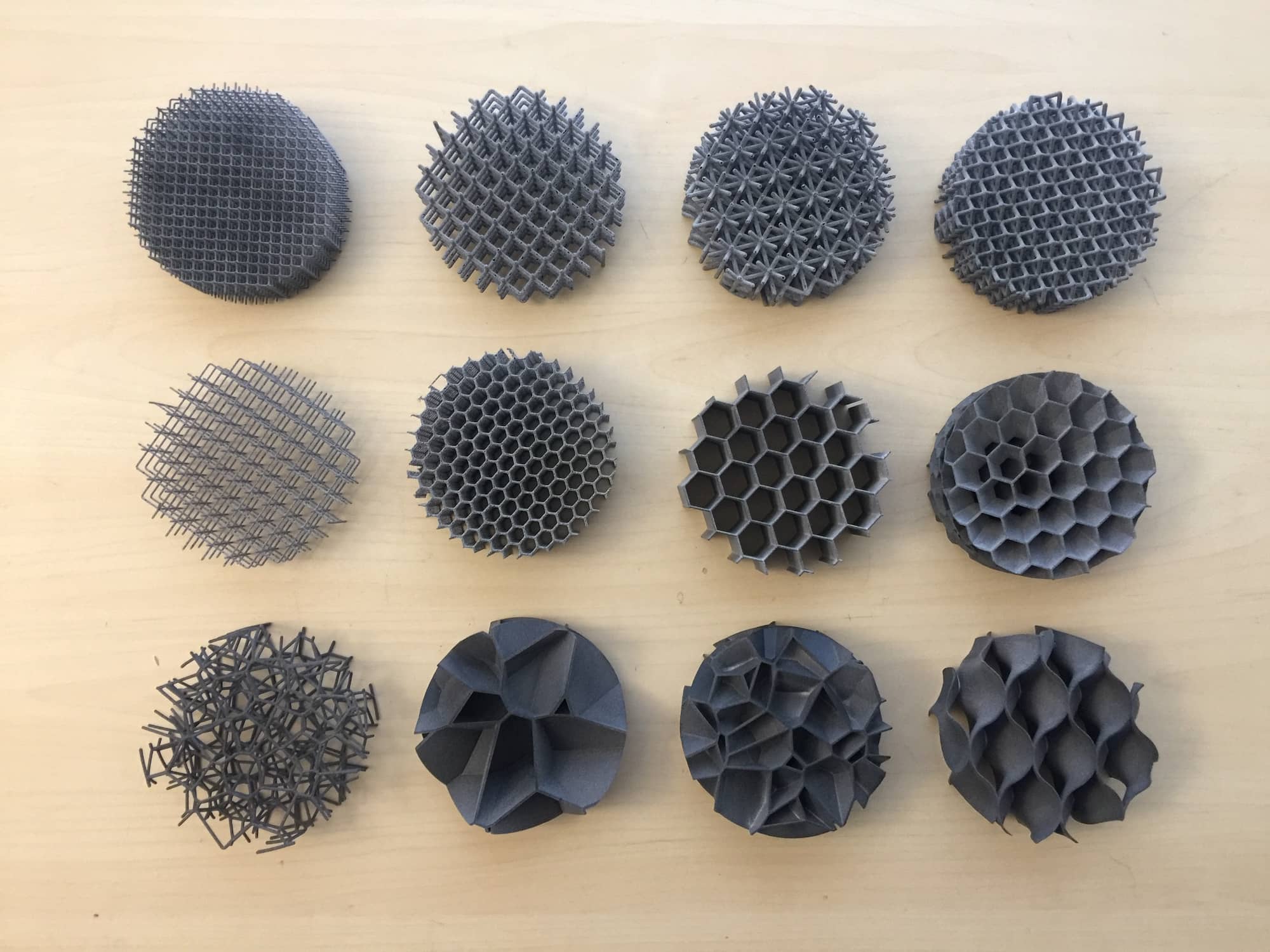

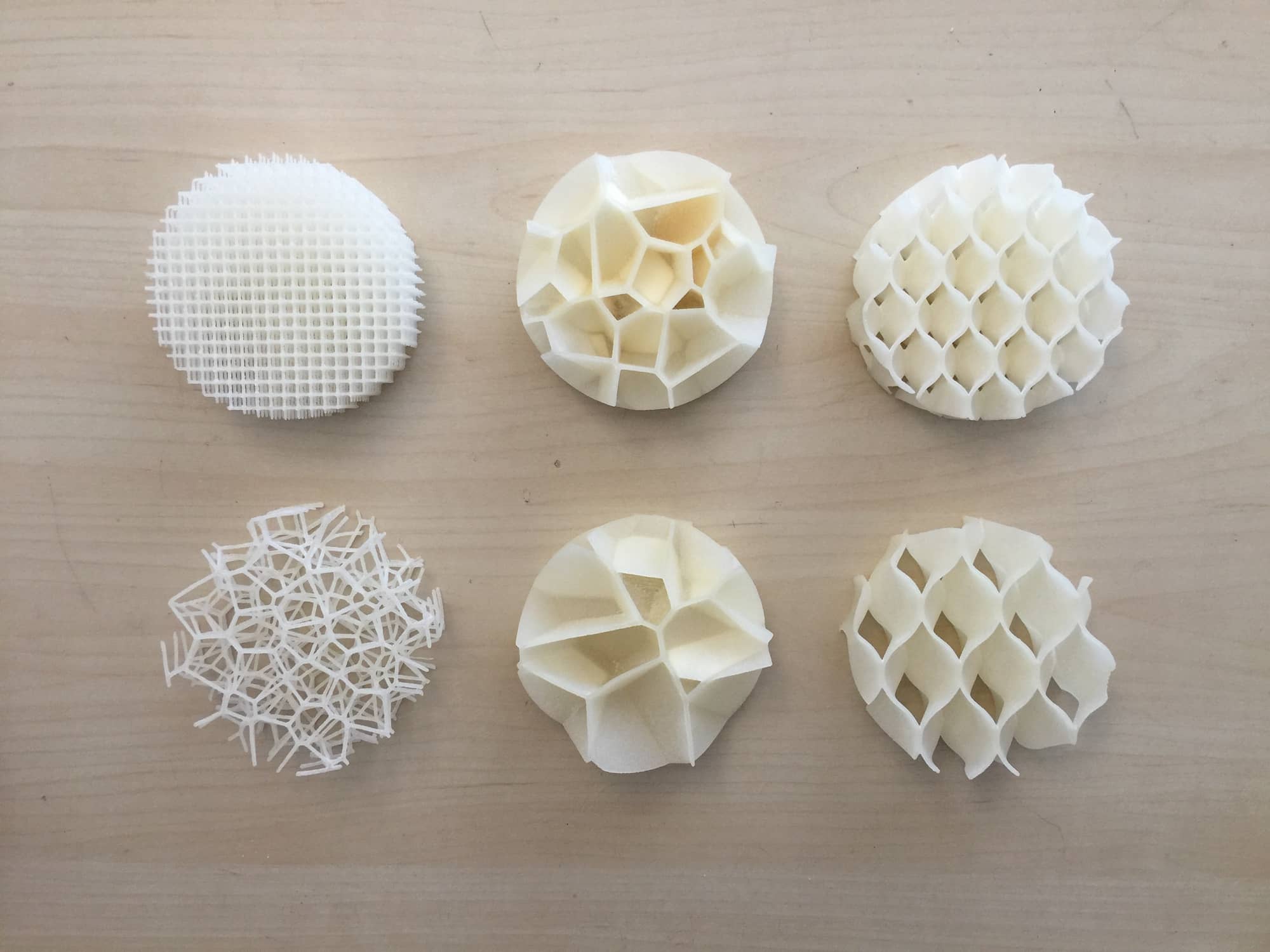

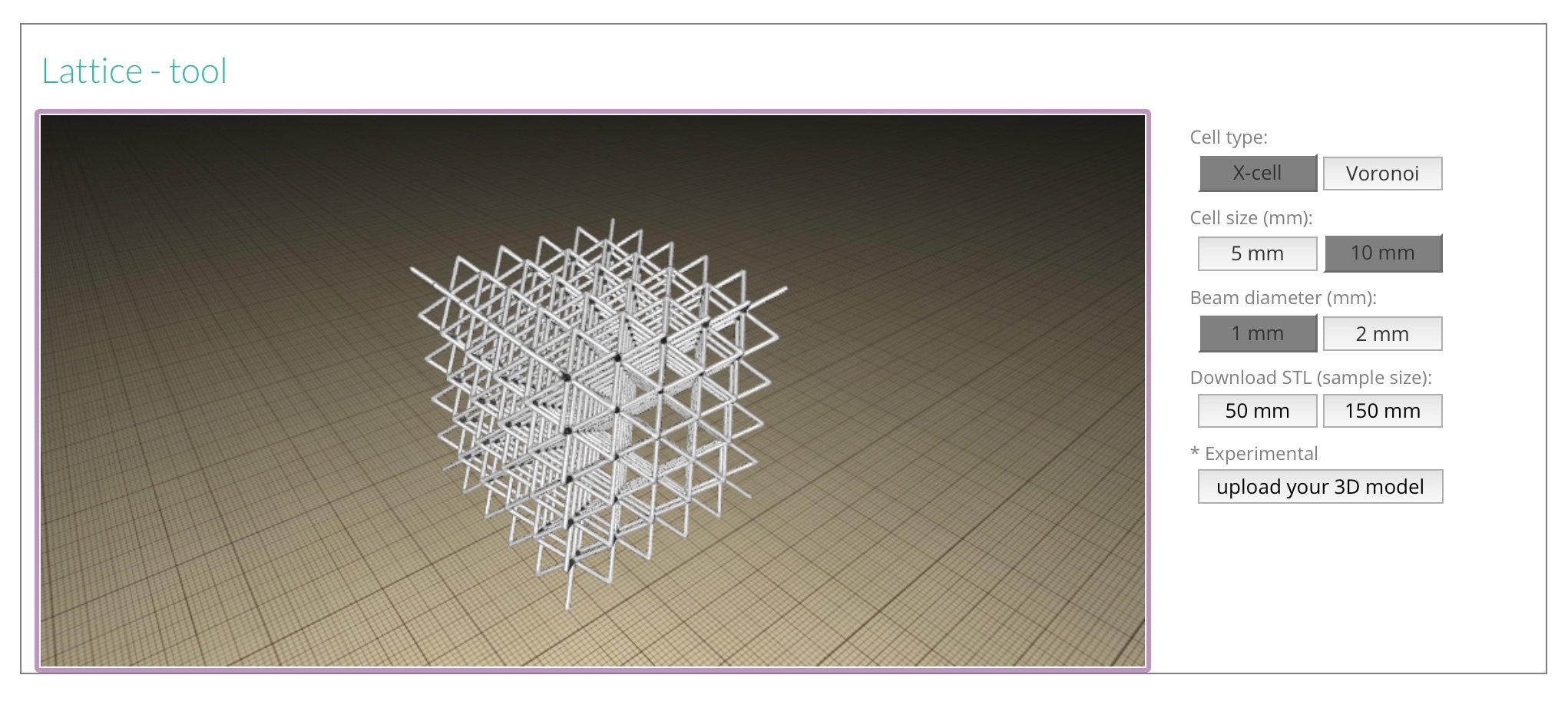

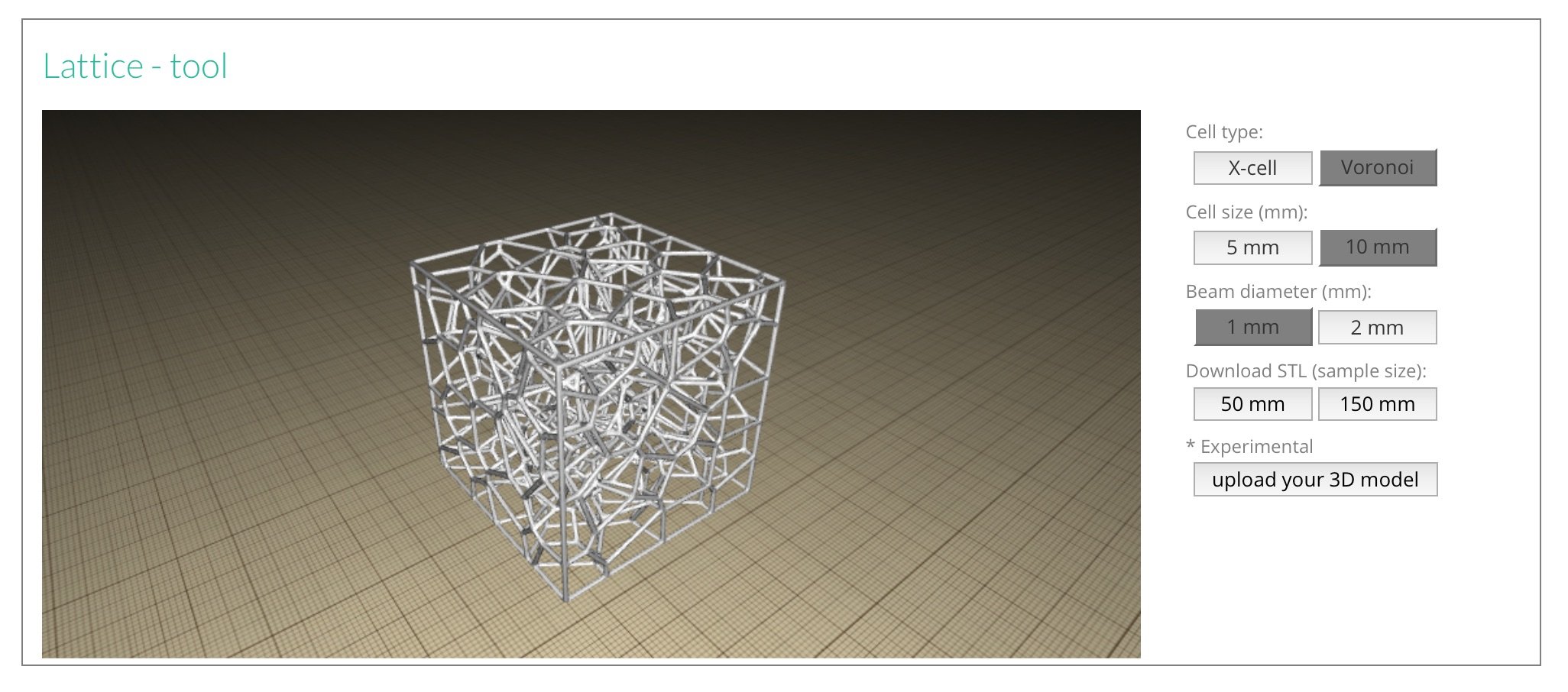

Design study on several techniques to generate lattice structures.

Dynamic Impact Tests

Test consisted in dropping 5 kg round metal object onto the test subject from a height of 1m. Test was run at the User Partner lab, equipped with testing machinery, using the 1011e 1012_MAU 1002_2W ALU_SF equipment by CKL engineering (figure 3 left). Machine measures the total impact force which is absorbed by the sample, measured in Newtons.

Test results evaluation

Helmet inner part designed with shock absorbing lattice

prototypes & tests

LaaS / Lattice as a Service

This project has received funding from the European Union’s H2020 Framework Programme for research, technological development and demonstration under grant agreement no 768775.

Project supported by AMable and I4MS, done In collaboration with: ProductosClimax S.A.

AMable [AdditiveManufacturABLE ] provides support to SMEs and mid-caps for their individual uptake of additive manufacturing. Across all technologies from plastics through polymers to metals, AMable offers services that target challenges for newcomers, enthusiasts and experts alike.

I4MS -> The EU initiative to digitalise the manufacturing industry