Agencies

Use 3D Printing in your next project: designing and preparing 3D models for 3D printing.

3D Print for Creative Agencies & Studios

Use 3D Printing in your next project, we help you by designing and preparing 3D models ready for 3D printing.

🛠 Problem: You want to use 3D Printing but don’t know how to start.

⚡️ Solution: We will assess if the project is doable or no and help you to make it real.

✏️ About us: We have extensive experience with 3D Printing in multiple projects.

🤔 You are an agency and got a fantastic project, and are thinking to use 3D printing: either to make a trophy for an event, create props for a photoshoot, or produce a short batch of items for a campaign.

Great idea! Probably everyone in the team has heard about 3D Printing, but most likely no one knows how to execute it :(

so, you might have some of the following questions:

- which materials shall we use?

- can we make something in colour?

- can we make something with metal?

- can we make something with ceramics?

- can we make something with flexible material?

- where to 3D Print?

- how expensive can it be?

You might have some talented designers on your team, and hopefully some master 3D modelling applications.

Sounds perfect, you should be ready to roll, but turns out that none of them have extensive experience with 3D Printing :( thus, there's a high probability that what they can design can't be 3D Printed due to constrains on the 3D Printing process.

So, your designers might have some of the following questions:

- how to create something to be 3D Printed?

- can I print multiple parts in one go?

- can my design have interlocking parts?

- what is the appropriate wall thickness?

- can the model be solid?

- shall the model be hollow?

- what is a "watertight" 3D model?

- how to remove manifold edges?

👍 We have extensive experience with 3D Printing in multiple materials, we have produced unique parts for clients, master pieces for molds, small batch series for product launches, personalised trophies, jewerly and ceramic products.

We will help you to assess if the project is doable or not. - for free -

Choose the appropriate material.

Design and 3D model for an optimal 3D printing.

Find a 3D Printing provider near you.

And help you produce the parts.

How it works:

You will work with a skilled product designer to create a design for your project.

We can start from scratch or evolve a product and re-design it for 3D Printing.

1 / Consultation / free

Assess if 3D printing is the best tech for your project.

-> Chat with us, or schedule a quick meeting to discuss your thoughts.

2 / Project Brief

Understand project goals.

Design inspiration.

Define materials.

Estimate production costs.

3 / Design phase

An expert 3D modeller will envision and prepare your design.

Iterative sessions where you will provide feedback in order to match expectations before production.

We will deliver a 3D file along with a final quotation of the production costs.

4 / Production & Shipping

3D Printed parts are made and delivered.

We will help you order the 3D Printed products with the 3D Printing bureau that best fits your needs.

Our production partners are in USA and EU, and serve globally.

What you get:

Up to 3 design iterations

Ownership of the digital 3D file.

Printability guarantee

*cost of 3D printing is not included

Approximate costs:

As a solution-based studio, we understand that price greatly depends on complexity of the problem to be solved, nevertheless, our experience creating designs for 3D Printing, allows us to set a tiered-price, that works in most cases:

3D Doctor:

> 1000 €

Projects where a 3D file is provided and needs minor tweaks to make it 3D printable (i.e Generate a valid geometry, thickness, hollow a model...)

Sketch to 3D:

> 5000 €

Projects where a clear idea, style and dimensions of the final object is drafted and needs to be modelled specifically for 3D Printing.

Concept to 3D:

> 9000 €

Projects where no prior design work has been done and ideation + design + modelling is needed.

XR Design

AR/VR experiences for brands and custom projects

Design for Mixed Reality

Exploring AR/VR tools for creativity and augmented experiences.

AR/VR projects brands and custom projects

Tools & Platforms

Augment your projects and make them available in multiple mediums.

iOS Ready - natively load 3D models and animations in AR

Unity - merge your content with a game engine

Dedicated Apps - enrich your project with a AR/VR app

Cross-platform - Oculus / Vibe / PlayStation VR

Creation in VR.

Experiment with the newest tools and creative software to create unique content.

Shareable

Publish 3D content on webBased galleries

Gallery

Explore some of our models

3D Scan

Creating a high detail digital archive of our material environment.

Using multiple 3D scanning technologies we can create high detail digital copies of our material environment.

HighRes scans for the creative industries, CGI, Gaming, AR/VR productions, educational content and cultural preservation.

High resolution texture maps,

HDLP - HighDefinition/LowPoly models: Manually retopologized from millions of polygons to an average of 5k-20k with HD NormalMaps.

Computer Graphics Imagery (CGI) reigns most of the contemporary media. (Did you know that H&M uses digital female 3D models on their website? and that what you see on the IKEA catalog is digitally crafted? and that the food that appears on commercials is also 3D?).

The omnipresence of CGI, combined with the rise of AR/VR platforms and the accessibility of 3D Gaming engines, creates the need for content.

We (humanity) made lots of stuff to ta date, and now, that stuff can be digitally captured and archived for digital re-use.

Some samples of models captured with photogrammetry:TreeBark scanned to design the TreeRing / here a making-of tutorial

Experiments

Design & Software Solutions for Additive Manufacturing

Design & Software Solutions for Additive Manufacturing

Additive Manufacturing allows for creative fabrication of unique parts and prototypes.

Designing specifically for this technology we can make impressive products suited for multiple applications.

Example:

meta.materials

Designing material behaviour through internal structures.

Lightweight: Reduce volume.

Custom Performance: Variable density lattice.

Optimised for AM materials and manufacturing methods.

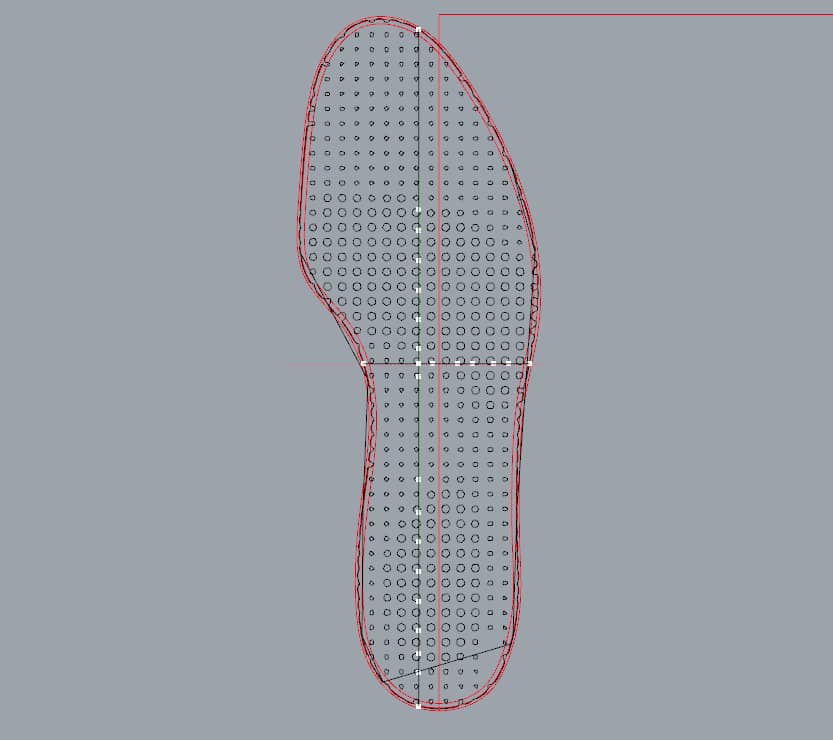

Project Sample:

Shock absorbing insole.

Biometric data-driven variable density lattice structure.

Design of a shock absorbing lattice structure.

Populate the insole volume with the designed structure.

Align the insole with a 3D scan of the wearer’s foot.

Define the performance of the insole by selectively assigning different density to the lattice structure.