JANA

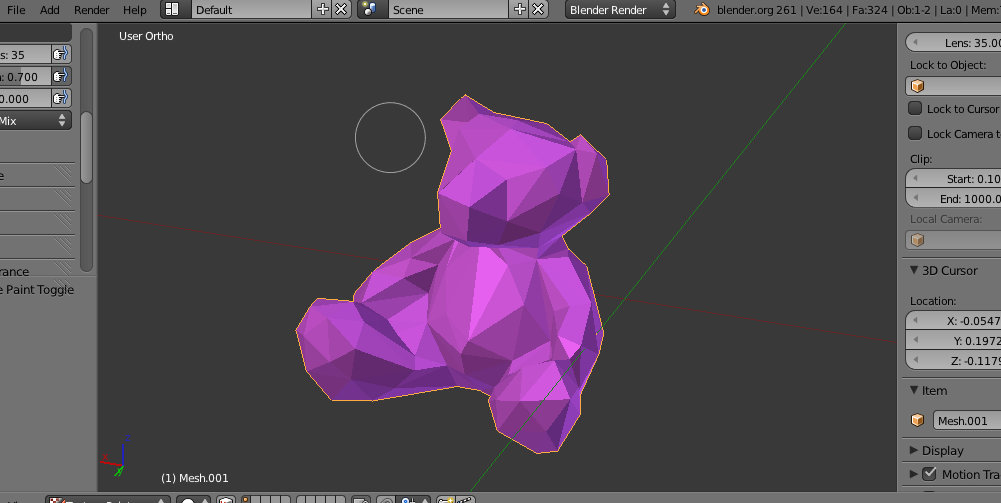

An ongoing collection of 3DPrinted toys based on a 3DScan of a real teddy bear combined with textures and modeling deformations. Each Jana model lives digitally in a server, and they are teleported to the physical world just when needed. The toys are made on-demand, they don’t exist until they are bought.

This is Jana, a teleported teddy.

he just got 3D-Scanned, poly-abused and texturized.

Jana is 1.5in tall (38mm); perfect for sitting on your desk watching you surf the interwebs.

She is cool, just take some photos every now and then, and she’ll be happy.

Jana loves music, loud and noisy if possible.

Get some of them, and they’ll entertain themselves.

3D-Printed in full color, a very nice material with a sandstone finishing.

Jana Harlequina

Jana is made of 324 triangles, randomly colored.

The primary aspect of Arlecchino was his physical agility.

While generally depicted as stupid and gluttonous, he was very nimble and performed the sort of acrobatics the audience expected to see. The character would never perform a simple action when the addition of a cartwheel, somersault, or flip would spice up the movement.

Jana at the Seven Seas

Jana Rainbow

Jana fully covered by rainbows.

Because double rainbows are too mainstream!

“In my world, everyone’s a pony and they all eat rainbows and poop butterflies!” - Dr. Seuss

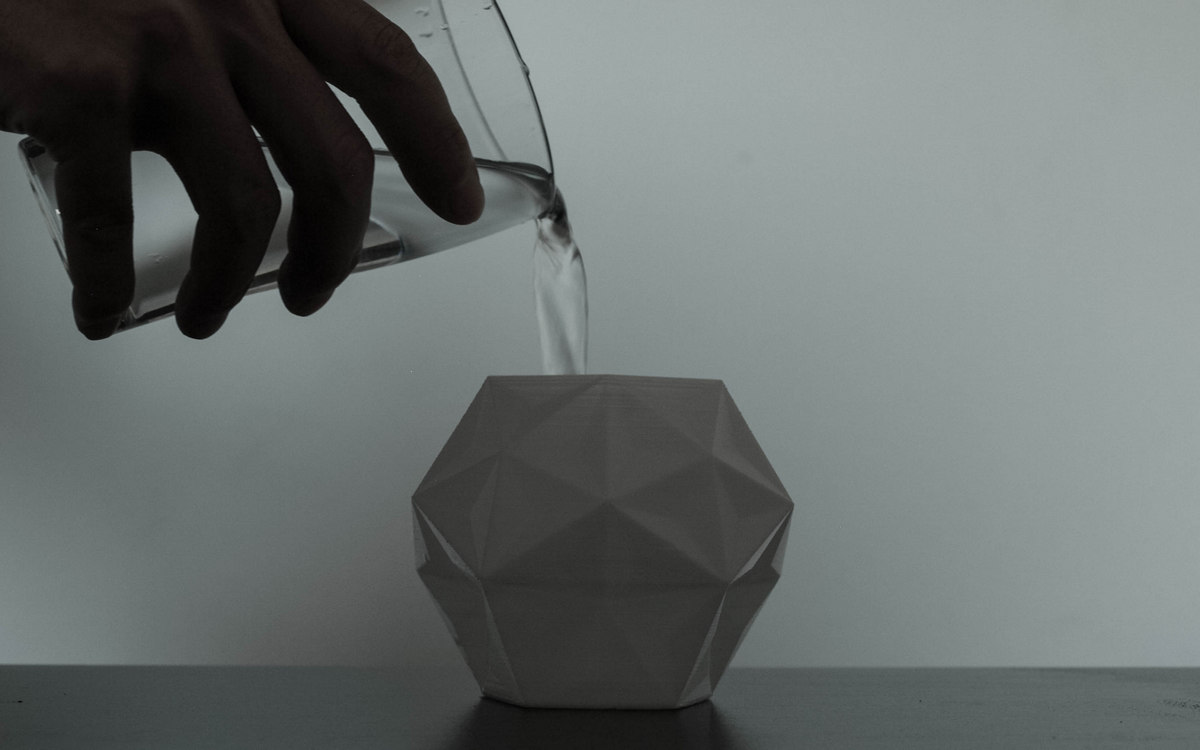

Jana BathTime

Built with a skin of bubbles and a hollow body.

Inspired by the Pix-Cell works by Kohei Nawa.

3D Printed in Red nylon.

Jana Fetish Black

3D Printed in shiny black glazed ceramics, this Jana got a sleek fetishist look & feel. She is the big sister, 2 inches tall (50mm).

Jana Hong Kong

Topographical Jana,

wrapped with the Hong Kong Harbor.

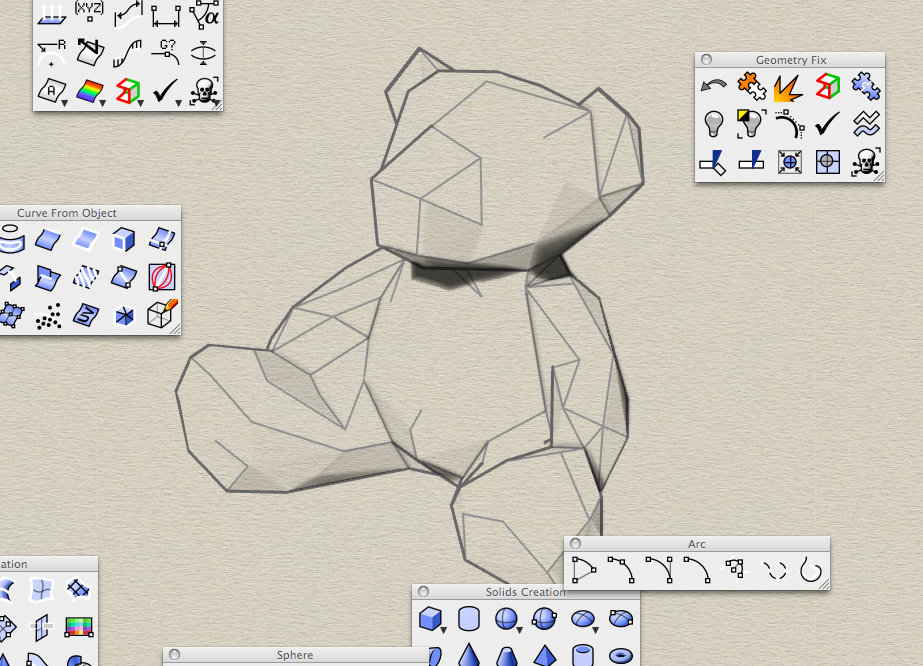

Jana Skeleton

Real bears have bones inside,

Teddy Bears have cotton,

but Jana has polygon vertices.

Jana Sketchy

Jana painted from a kid’s drawing.

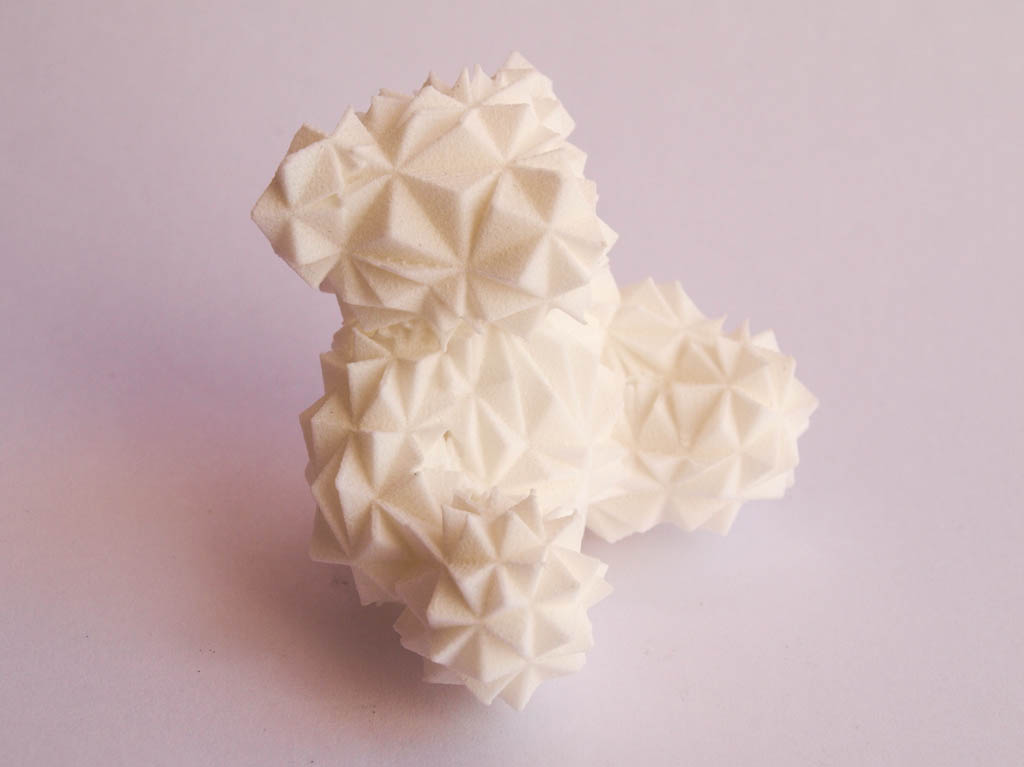

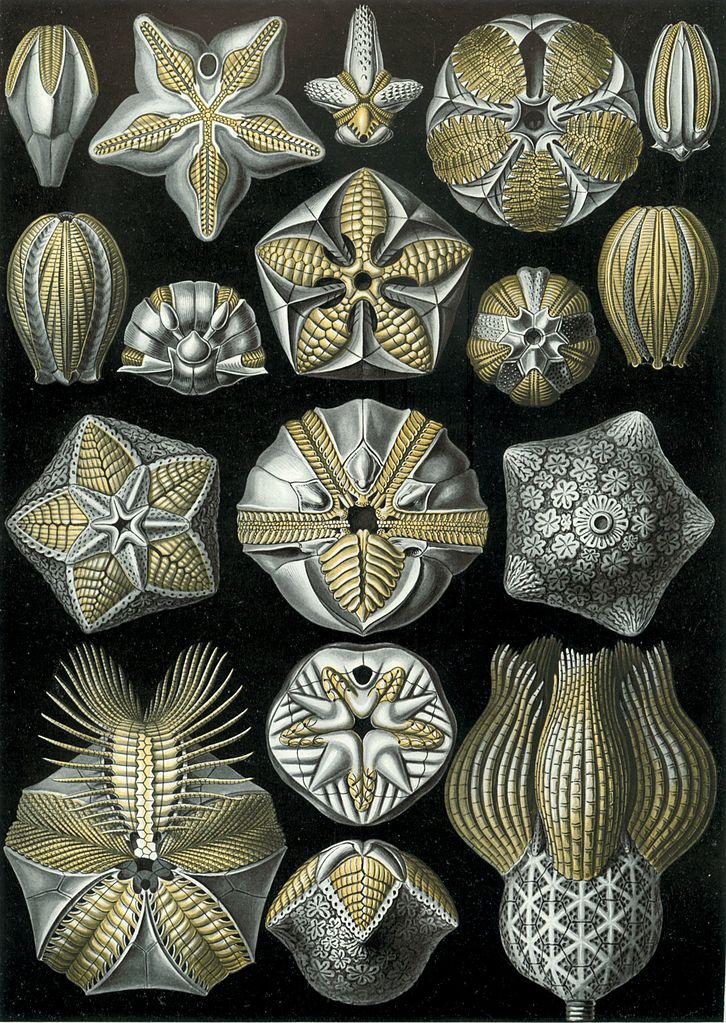

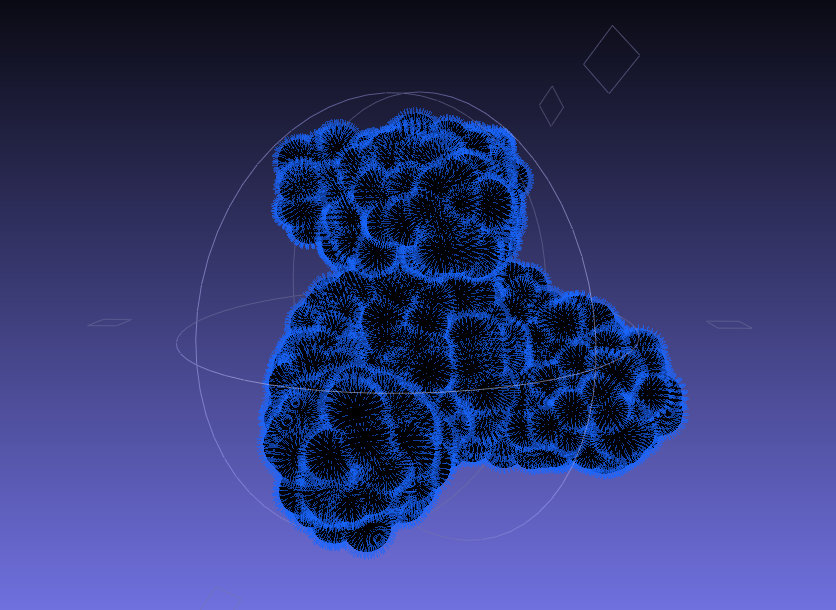

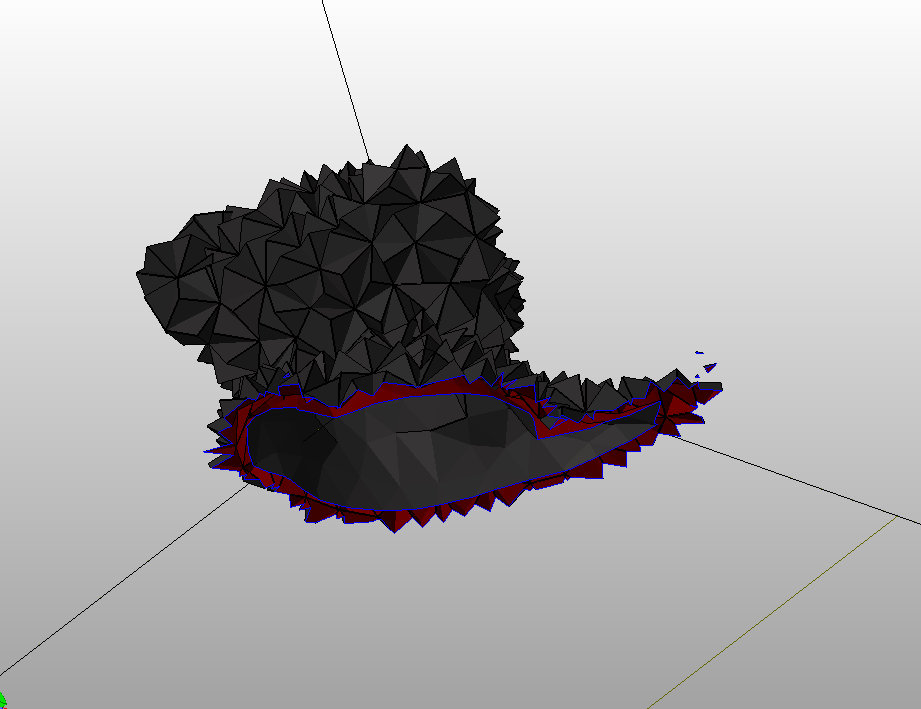

Jana and the Urchin Affair

Spike filled Jana, like one of those lovely echinoidea drawn by Ernst Haeckel at the Kunstformen der Natur

About

Jana is an ongoing collection of 3DPrinted toys based on a 3DScan of a real teddy bear combined with textures and modeling deformations.

Each Jana model lives digitally in a server, and they are teleported to the physical world just when needed. The toys are made on-demand, they don’t exist until they are bought.

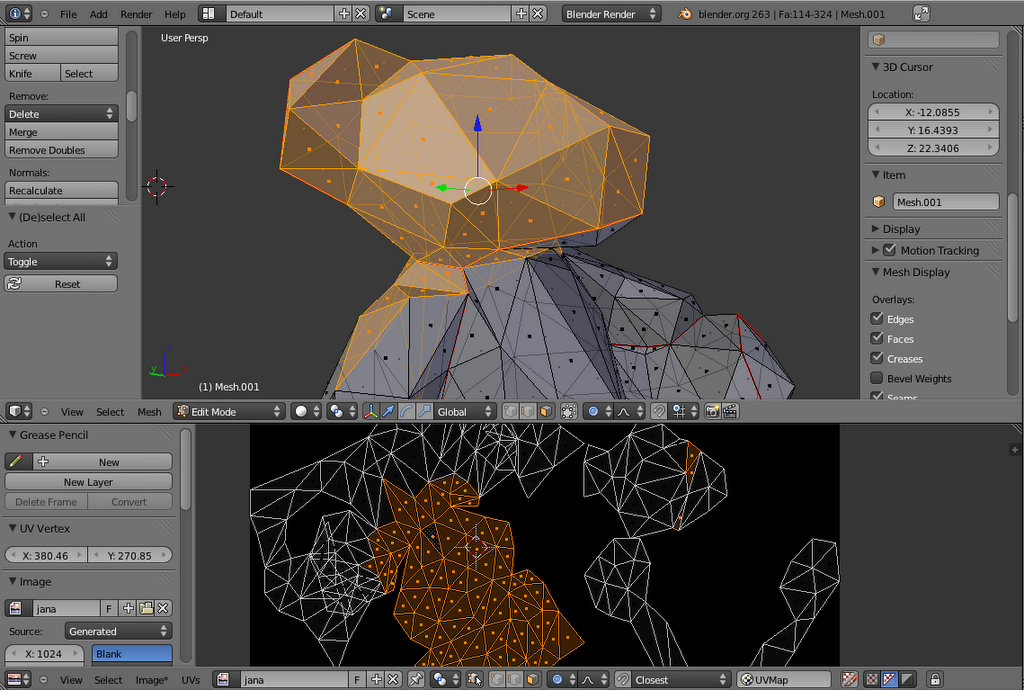

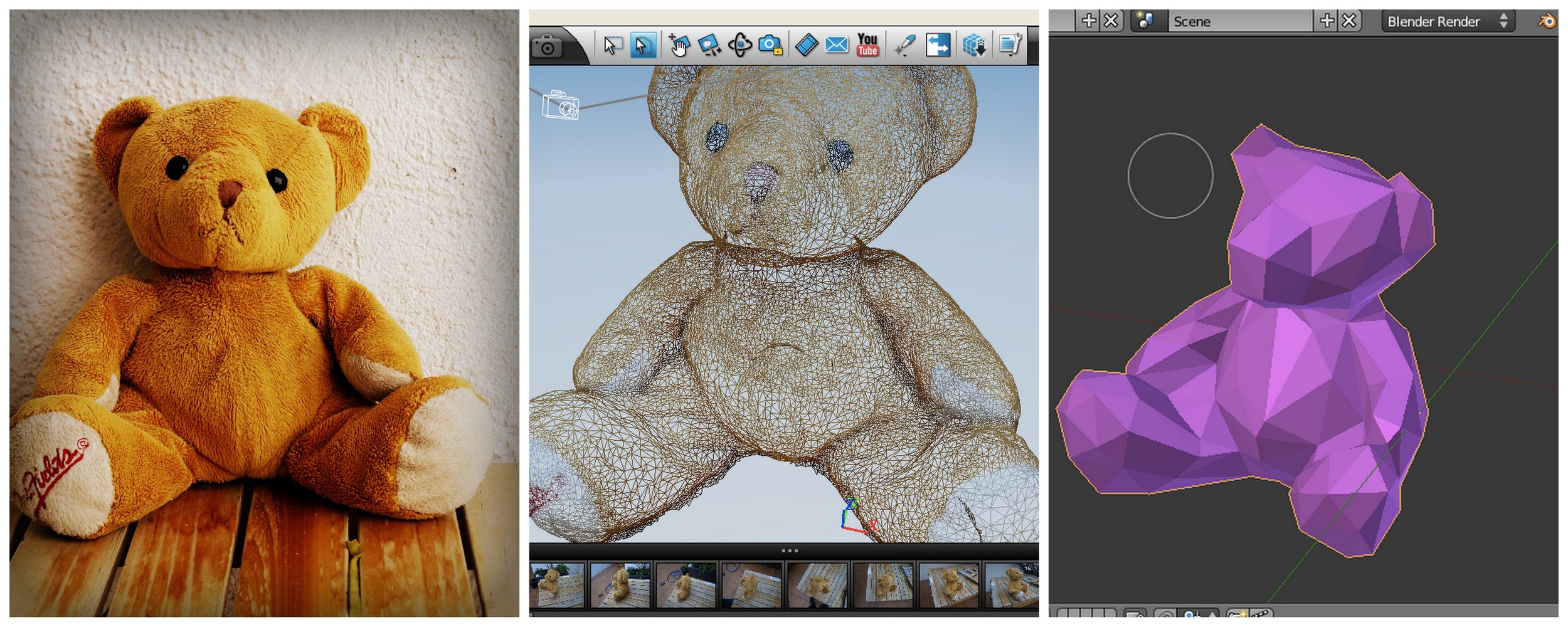

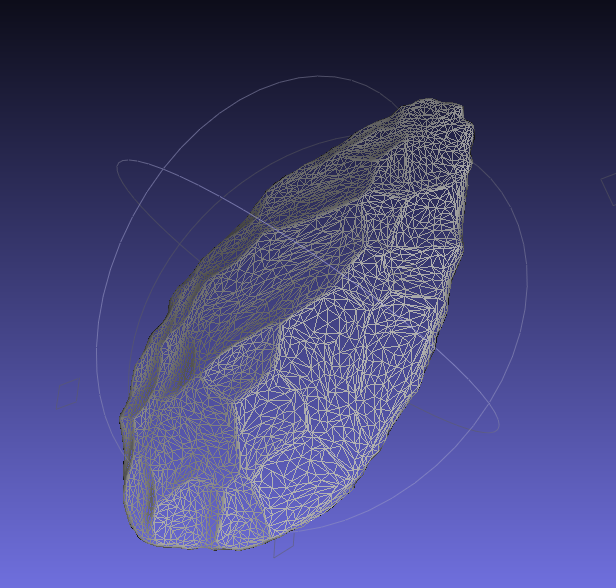

Process

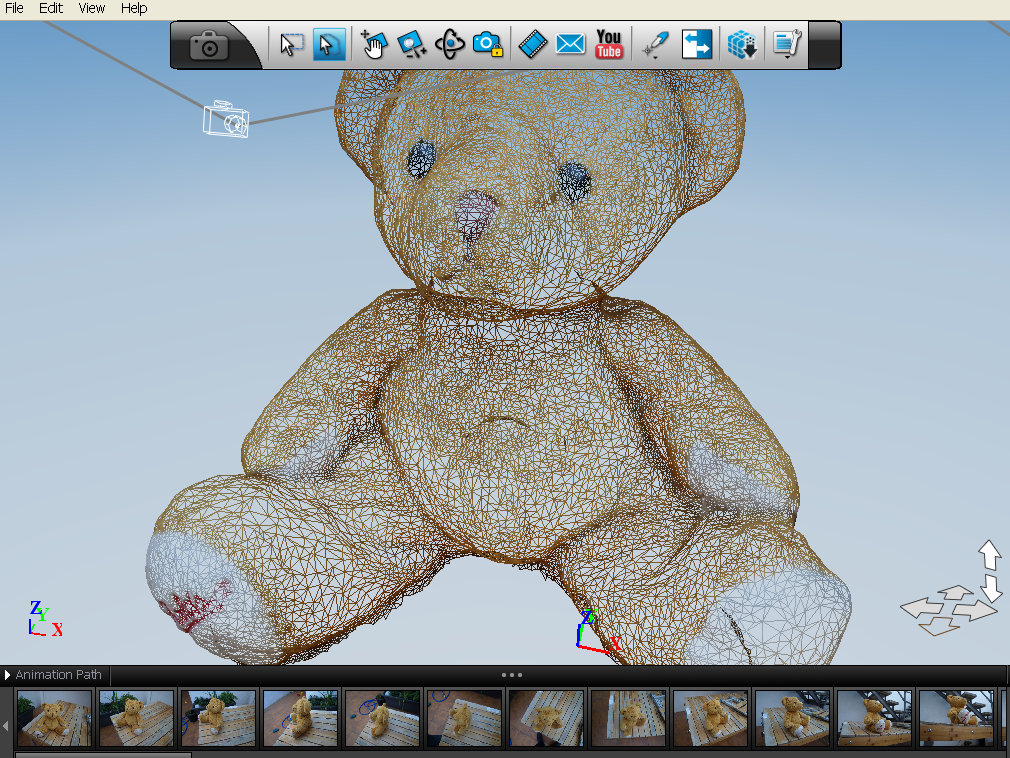

Jana is the real Teddy Bear from a 5 year old girl,

It was scanned using the Autodesk 123D-Catch software,

The cleaning up and re-mesheing was done with MeshMixer.

The texturing and UV mapping was done in Blender.

Mesh edits were done with MeshLab.

Final fixes and file preparation for 3DPrinting was handled with Netfabb.

dilDIY – coDesigned pleasure objects / concept

coDesign application to make 3D Printed ceramic pleasure objects.

-> This project has been archived and removed from this site.

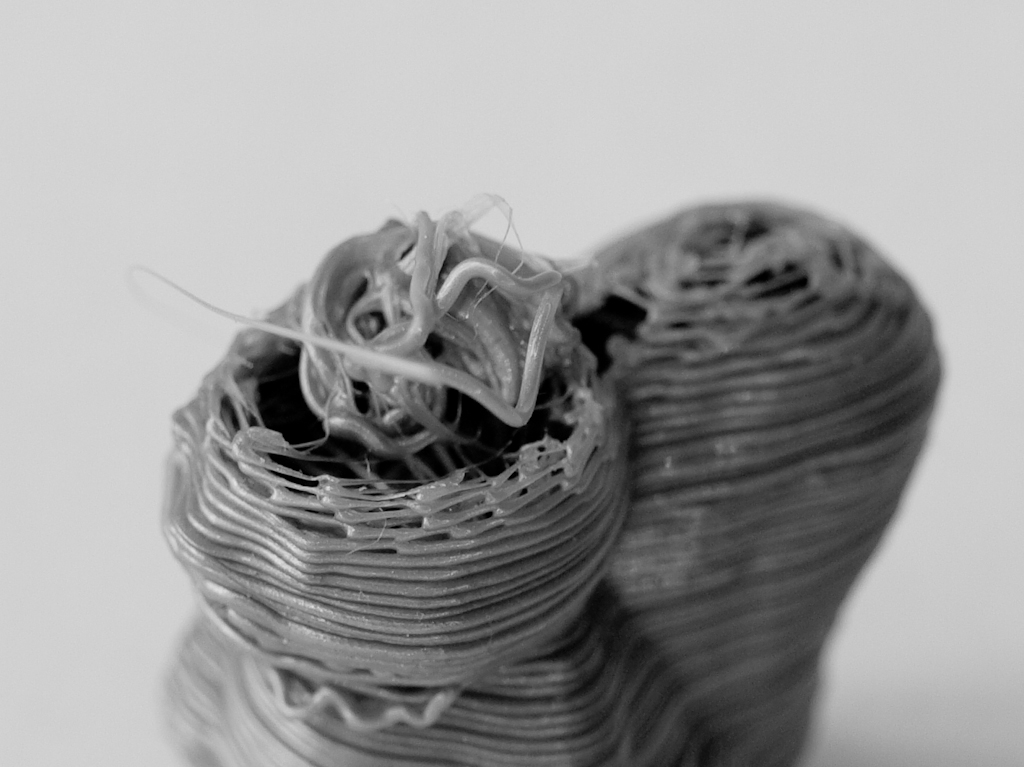

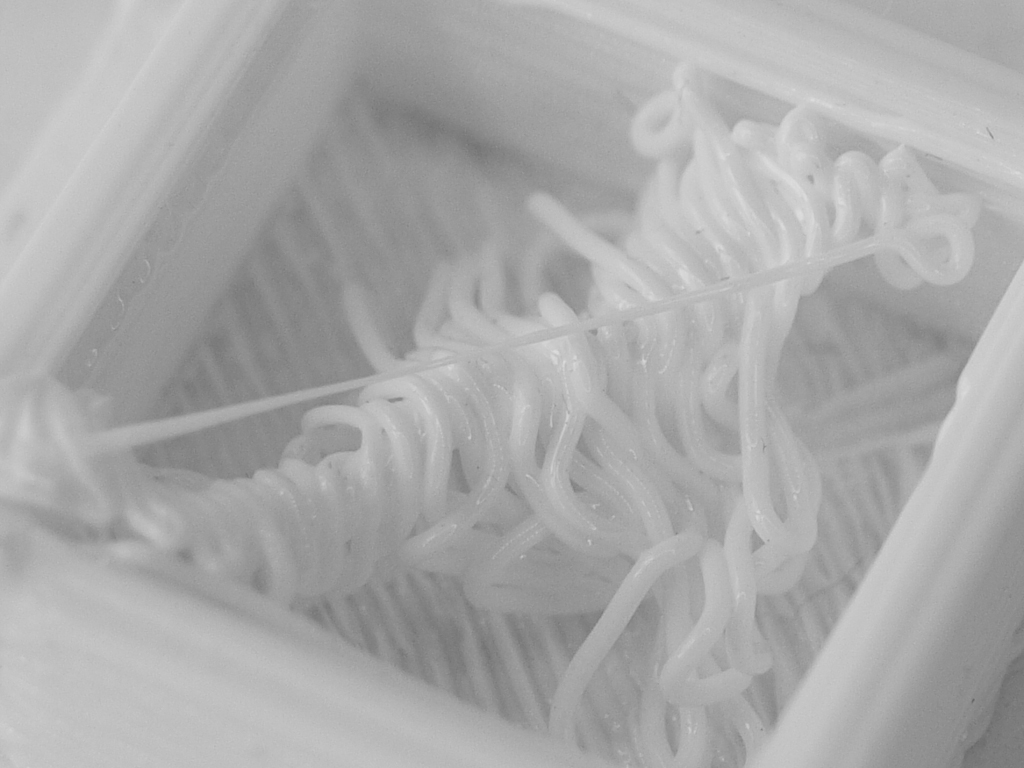

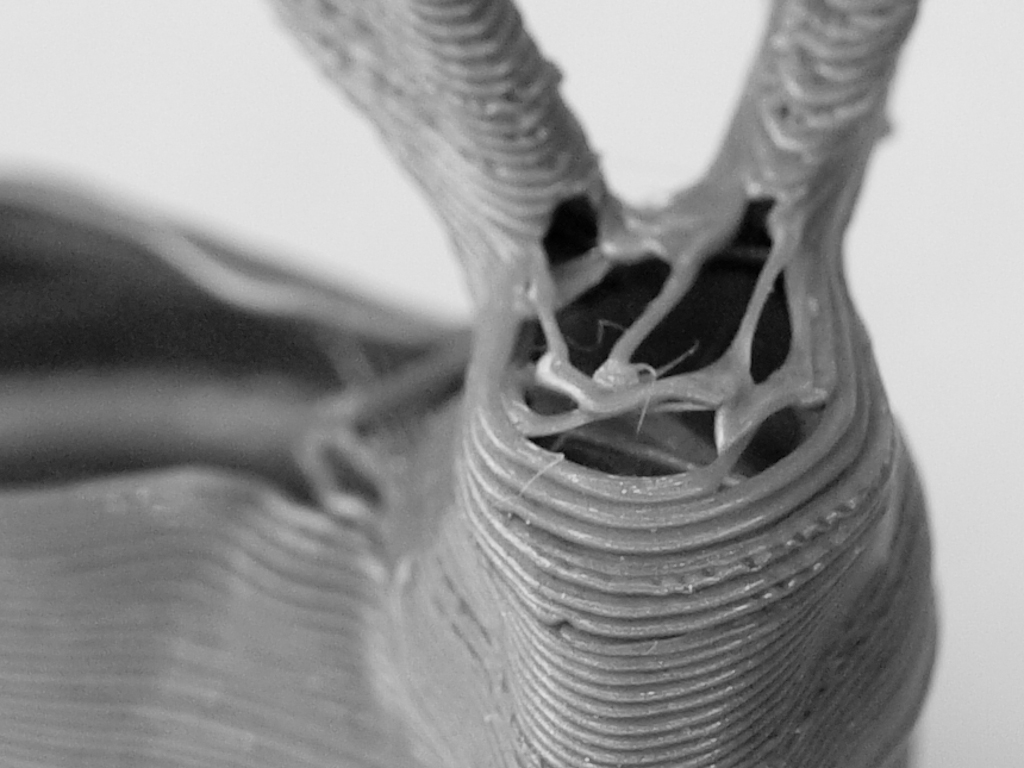

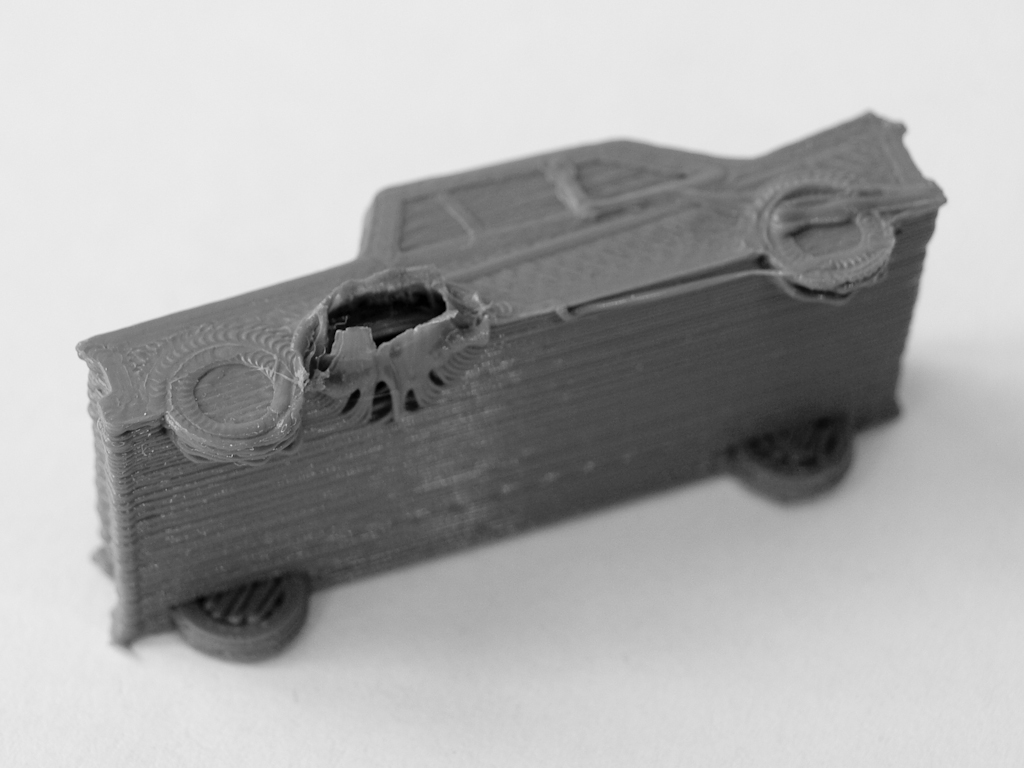

beautiful failures | accidental 3D Prints

On the path to get the perfect 3D-Print, many meters of filament get piled up as discarded disappointments,

as bastard objects that never were,

as unborn half-things…

… and they are beautiful.

A photographic collection of discarded pieces made with a domestic 3D Printer.

Back in 2011 I got my first DIY 3DPrinter, an Ultimaker, a very nice piece of hardware that builds whatever I command.

Mastering a 3DPrinter is a craft; it is earning a set of skills coupled with a set of tools.

In the process of domesticating my 3D Printer I had to figtht with hundreds of variables, thousands of settings and millions of lines of GCode.

I can’t describe well enough the joy of getting your first object 3D printed as intended, but it is a huge success.

But, on the path to get the perfect 3D-Print, many meters of filament get piled up as discarded disappointments,

as bastard objects that never were,

as unborn half-things…

… and they are beautiful.

Ever since I first saw a 3D-printed object, I’ve been fascinated by the layered look & feel.

As a designer I call for honesty on product's aesthetics, I tend to like things that don’t hide their nature. Same with 3DPrinted objects, I like the texture and finishing of additive manufacturing, specially FDM (Fused-Deposition-Modeling).

nice? I also made a book.

Beautiful Failures - serendipity & the art of 3d printing

A video by Adam Proctor

What is it about failed 3d prints that piques our curiosity? Whilst ruined 2d prints are often just discarded, failed 3d prints may often be kept as aesthetically pleasing artefacts, with designers sharing their 'rejects' on forums and image galleries. Product designers are even manipulating code to force prints to 'fail' in the hope of discovering new printing methods and engineering solutions.

Contributors: Bernat Cuni Dr. Paul O'Dowd Dr. Peter Walters Music: Poddington Bear

StarVase

A nice vase with pentagonal sides.

Evolved from a dodecahedron, surrounded by stars.

A nice vase with pentagonal sides.

Evolved from a dodecahedron, surrounded by stars.

Robot made, in a domestic 3D-Printer.

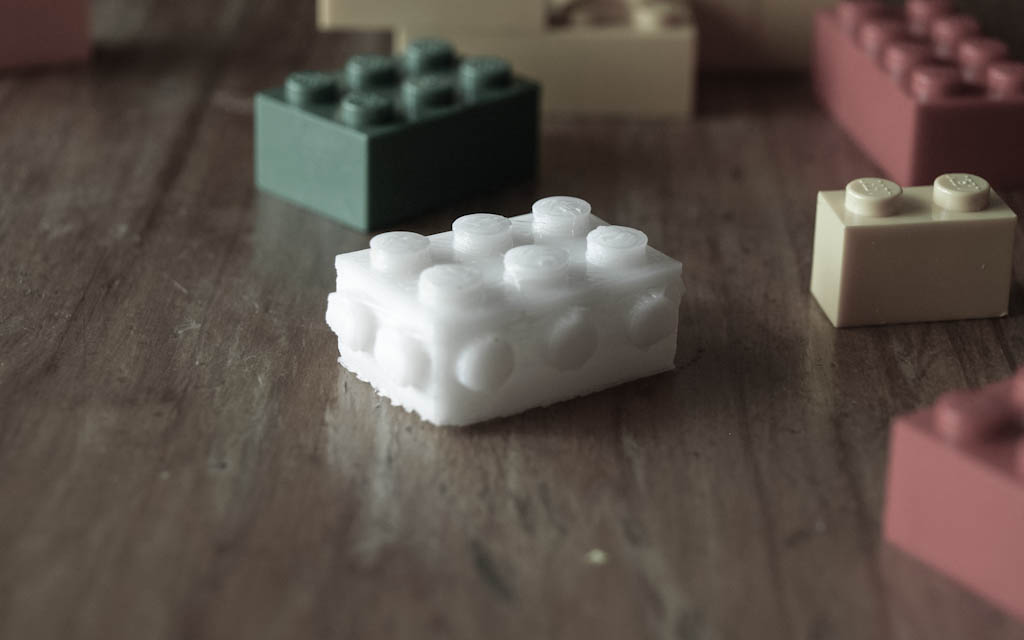

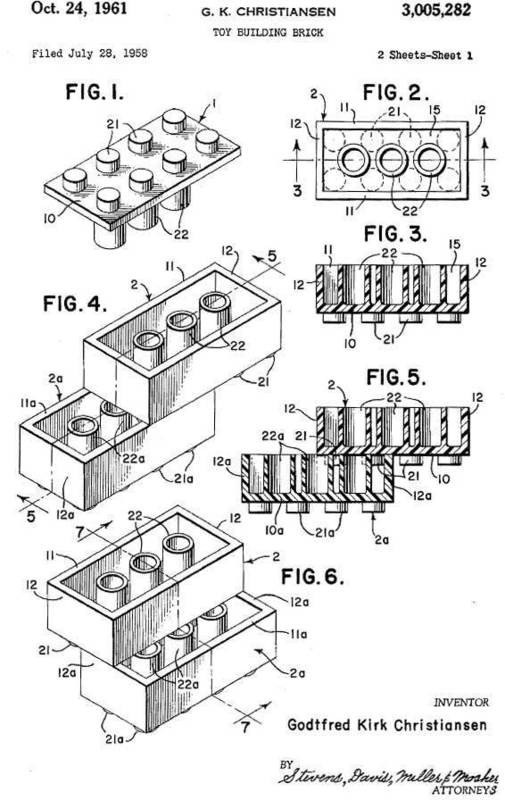

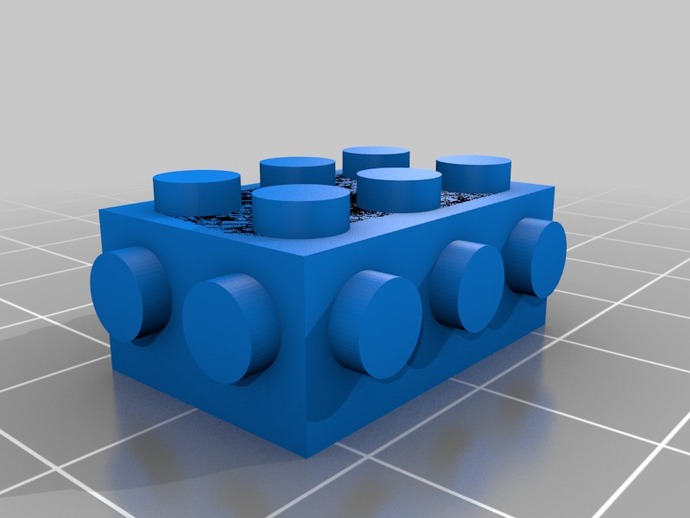

brick 2×3 = 16

A classic lego-like brick with knobs on every side.

A classic lego-like brick with knobs on every side.

Inspired by ffff.at Free Universal Construction Kit,

fffff.at/free-universal-construction-kit/

and the fact that Lego’s brick patent is over.

boingboing.net/2011/10/21/expired-patent-of-the-day-lego.html

Detailed dimensions and proportions of a classic Lego brick can be found here:

robertcailliau.eu/Lego/Dimensions/zMeasurements-en.xhtml

Print & share: grab STL files @Thingiverse

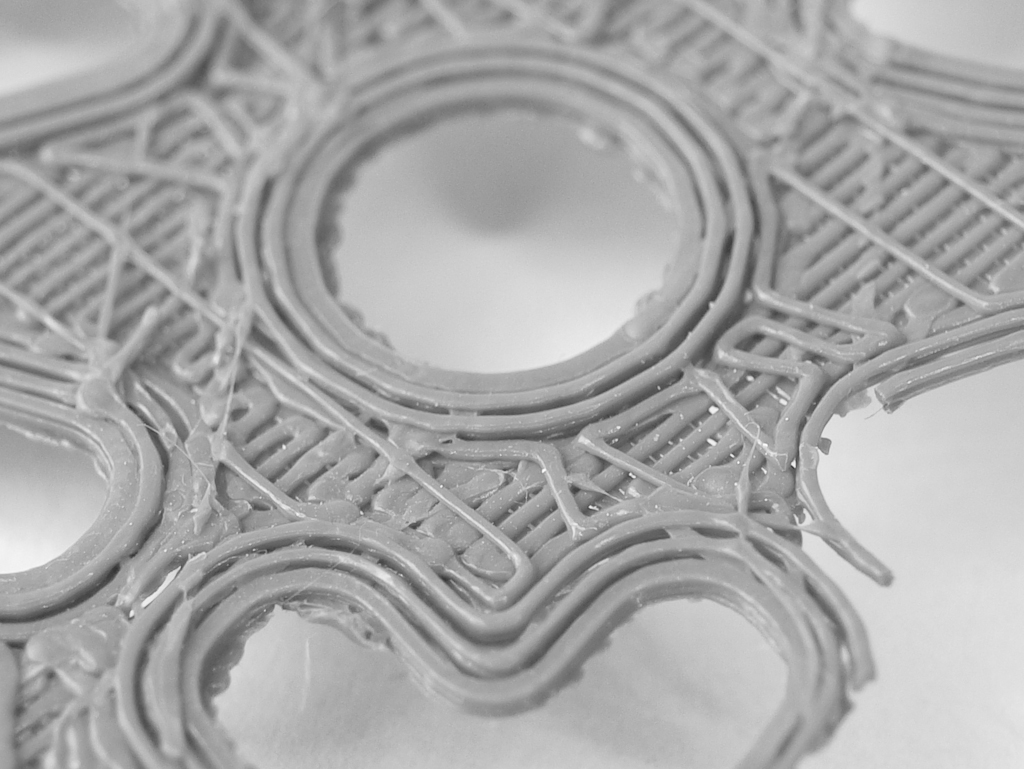

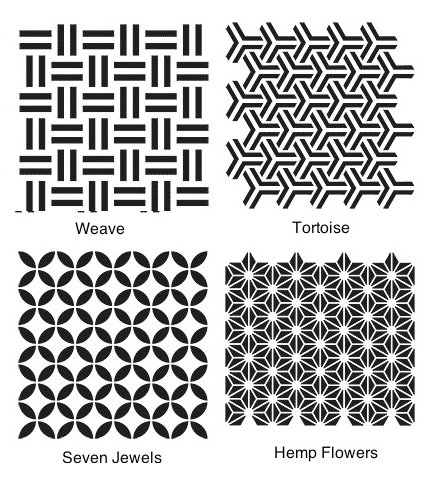

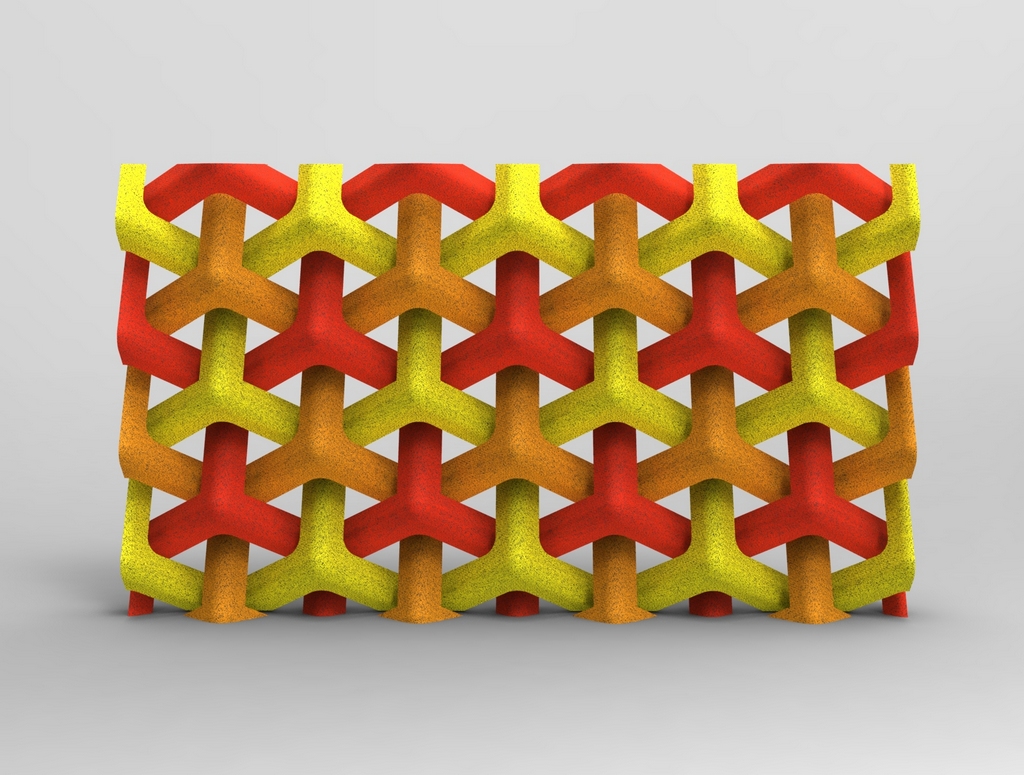

Structures & Lattices

Ongoing research on structures & lattices to enhance SLS 3D-Print properties.

3D printing allows for the creation of shapes and volumes never possible before,

thus, materials might behave differently when presented on new shapes.

Ongoing research on structures & lattices to enhance SLS 3D-Print properties.

3D printing allows for the creation of shapes and volumes never possible before,

thus, materials might behave differently when presented on such shapes.

Taking the Selective Laser Sintering process as the starting point for this exploration,

we have developed the following structures:

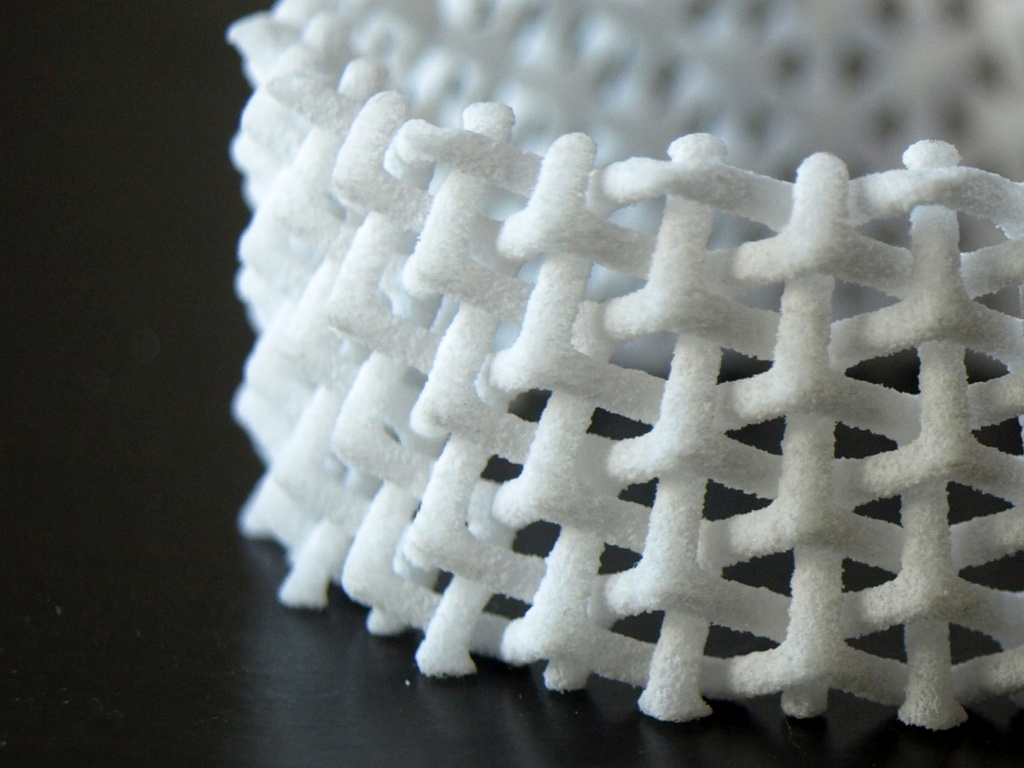

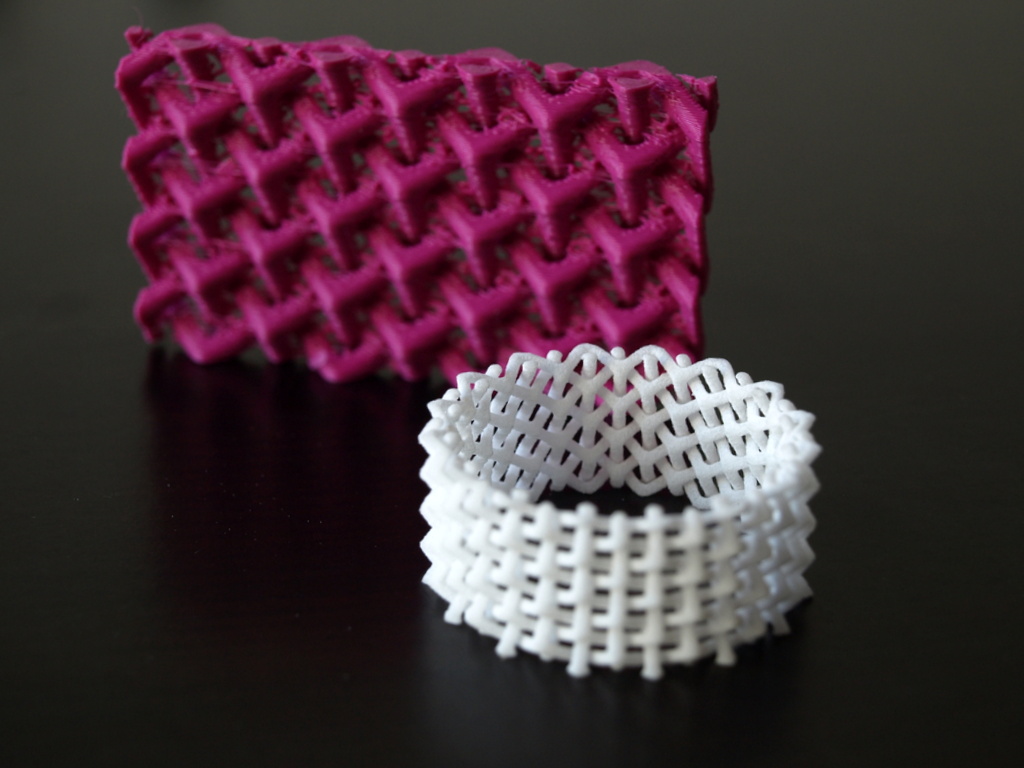

CubHex

Inspired by traditional Japanese patterns, this structure is composed by three interlaced structures build with 90 degree connections that appear hexagonal when seen frontally.

This structure is suitable for external walls and parts that require strength in one axis but demand flexibility in another, like this example of a cylinder, which is incredibly strong in height direction, but the circumference has certain deformable tolerance.

FleX2

Structure capable to flex in various directions.

The repeating unit, features connected curvatures for maximum stretchiness.

DoubleHoney

Stiff structure is composed by a stretchiness grid of connected bridges.

Expandable structures

Since one of the big limitations of 3D-Printing is size,

it wold be great if we could print folded parts that expand once printed: Think printing an umbrella.

Selective SLS technology is totally capable of printing interlacing and moving parts,

so, it is a matter of finding the right structure to minimize printing size and maximize volume and strength.

initially , I focused on designed a 3D version of the popular Origami Magic Ball,

Early results weren’t satisfactory enough; They involved too many connectors and hinges.

I’m still looking for the right proportions to successfully generate live-hinges in SLS,

if any idea, please share your thoughts.

About

Bonus: an inspirational video on how to quickly fold a t-Shirt.how to fold a T-shirt.

The idea to develop some enhanced structures for 3D-Printing came when discussing about Adiitive Manufacturing and Textiles with a colleague that was questioning the feasibility to print full body garments, so I suggested to print them folded.

Imagine; we could print filled-up wardrobes!

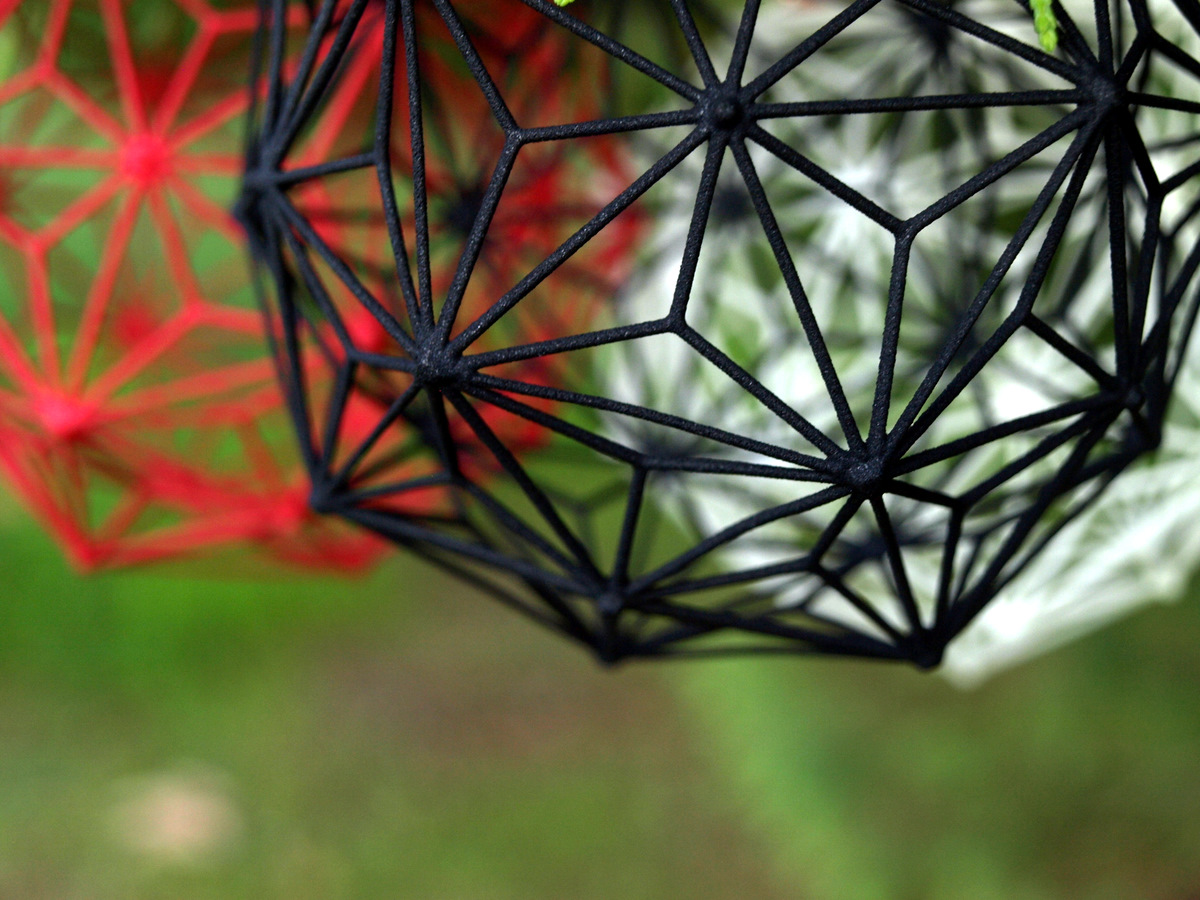

3D Printed Christmas Ball

A set of lightweight geometrical christmas decoration balls 3DPrintd in Red, White and Black.

Why?

Because it was christmas and I wanted to design & make something with 3D Printing that was price competitive with mass produced objects.

Since 3D Printing costs are driven by volume and material used, I designed the geometry of these balls to use minimum material while keeping maximum strength, resulting in a $5 costs. quite OK compared with fancy mass produced christmas balls :)

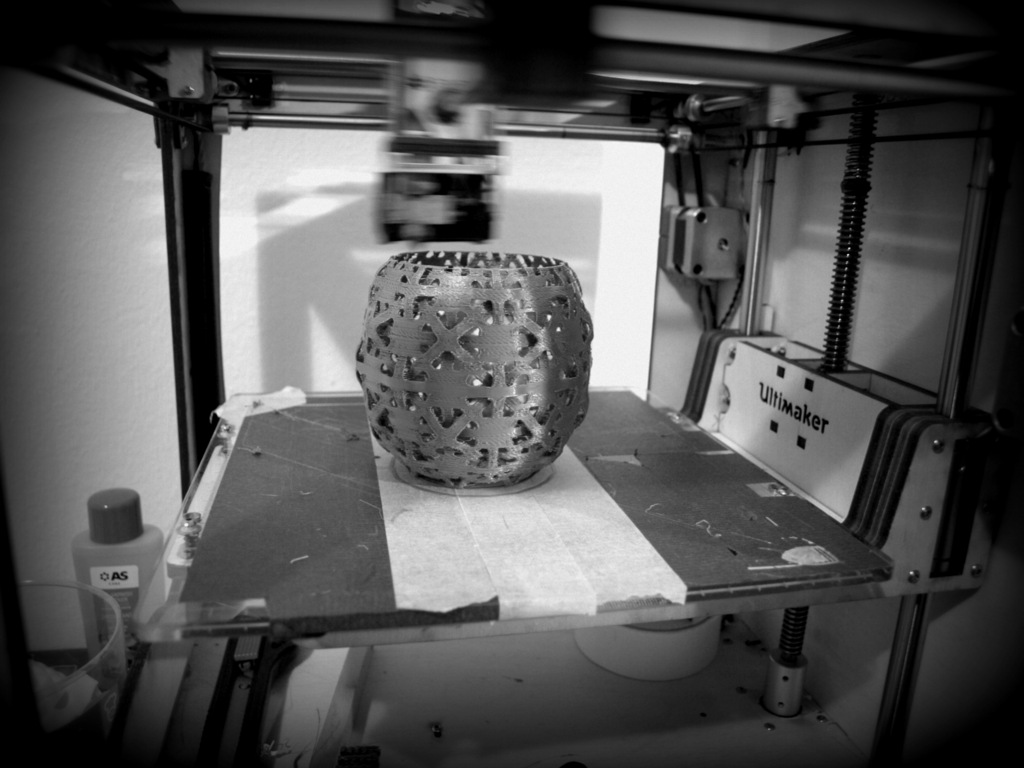

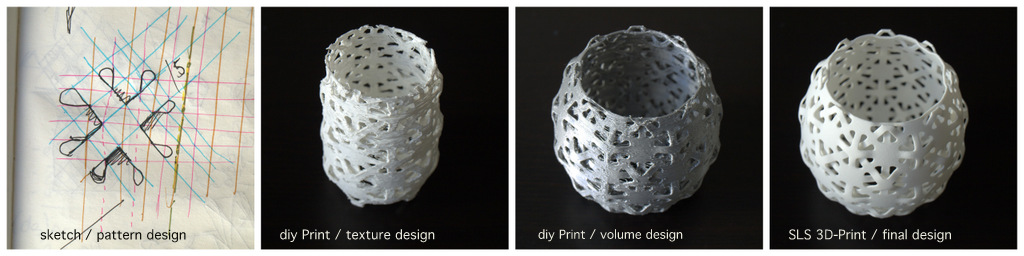

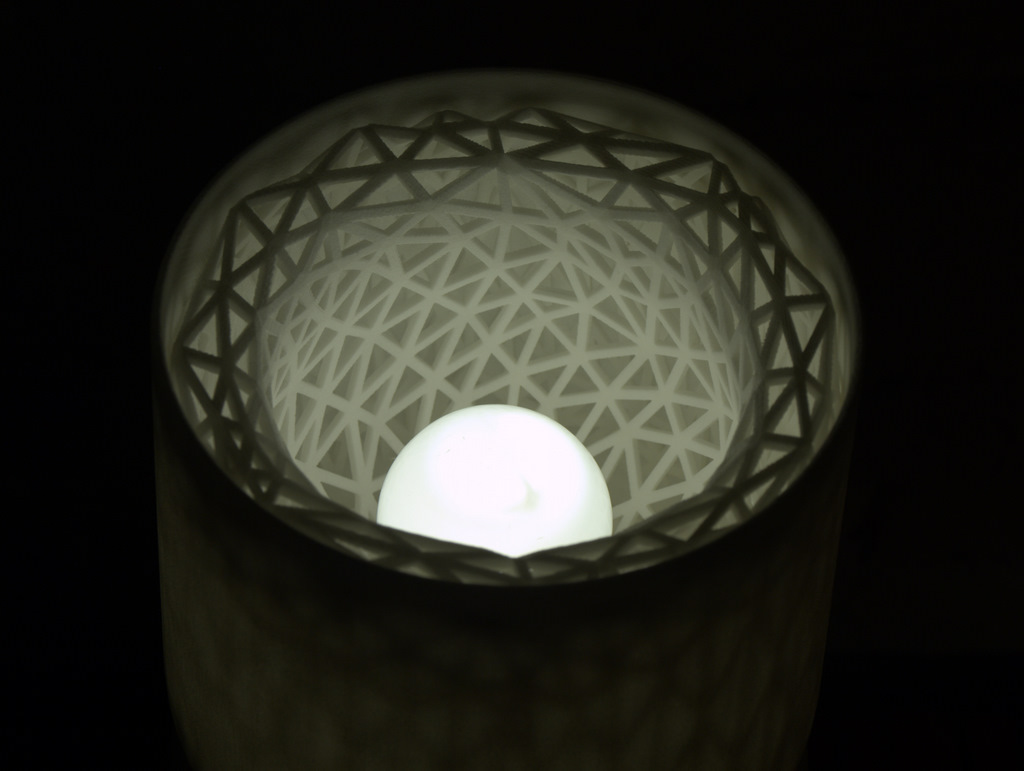

Mediterranea

3D-Printed lampshade inspired by mediterranean decorative tiles

3D-Printed lampshade inspired by mediterranean decorative tiles.

Dimensions: 100x100x95mm

lampshade fitting = 30mm diameter / suitable for all IKEA table lamps.

Small lightbulb, LED lightbulb suggested.

Interlaced design that creates beautiful pattern of light and shade.

Design & Development

After inital sketches, a surface pattern study was built with a DIY domestic 3D Printer,

The final design is produced in Polyamide by professional Selective Laser Sintering machines.

Do you like tiles?

There’s a fantastic poster at Designboom

And this iPhone skin also.

Available at shapeways.com

Contact for resale and distribution.

Stellate Collection

3D-Printed Home Accessories

3D-Printed Home Accessories

A collection of two lamps and a table tray made with 3D-Printing technologies featuring faceted surfaces and intricate stellate structures that appear when the pieces are seen through the light.

Computer generated shapes are generally built with wireframe meshes composing beautiful triangular geometries that normally are lost when the product is produced with traditional production methods like injection molding.

3D-Printing technology, being a computer controlled process that builds objects by adding thin layers of material one on top of another, it allows for those geometries to be translated into physical objects.

The Stellate pieces have a quiet design approach avoiding loud over-exposure of complexity.

The internal triangular structures live inside the objects and shyly appear throughout the external surface as a reminder of the birthplace of every object; the computer 3D modeling environment.

These simply shaped objects hide their complexity at a first sight, and only showing it to viewers who pay a second look.

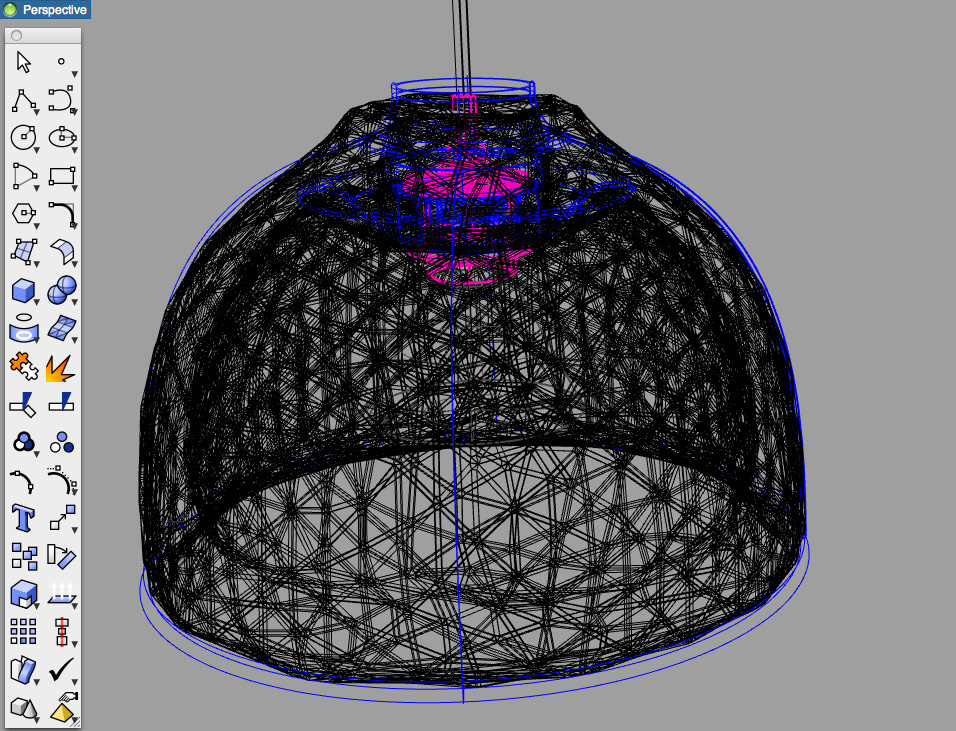

Stellate Pendant Light

Dome shaped filled with a triangular wire structure

Stellate Table Lamp

Simple truncated cone with an internal mesh of triangles.

Stellate Tray

Concave bowl with a hidden mesh underneath it.

The Process:

3D-Printing final products shortens spectacularly the product development process.

Comparing the 3D-Printing process to the process followed by a mass produced light, the time and costs are reduced drastically.

The resulting pieces are fully functional products ready to be produced on demand, with the plus of offering space for customization and special requirements.

A) Design | product concept & sketches

B) Computer Model | sizes, proportions, details & fine-tune

C) 3DPrint | prepare the file, wait & clean up.

Product Launch: Moscow

The Stellate Collection was presented to the public in Russia during the DesignAct fair in Moscow, 8-11 September 2011.

The Stellate Collection, is produced on demand via 3D-Printing technologies, allowing for customization and client specifications.

Each lamp can be unique. Please contact us for delivery times and costs.

Credits:

Designed by Bernat Cuni.

Produced by Fundació CIM using 3D-Printing SLS Selective Laser Sintering Technology.

The Fundació CIM offers a wide range of technological services helping organizations to be more productive, improving their industrial processes and raise the quality of their products to compete successfully in global markets. The benefits of these services are intended to finance research projects, to renew the machinery and the provision of scholarships for technical careers. The main purpose of the Fundació CIM is the generation and transfer of knowledge & technology to the society. From the conception of a product to marketing, one must generally resort to different professionals and partners, representing a waste of time, information and project control. To minimize these drawbacks, the Fundació CIM supports the development of products from the design to the production phase.

BumpBangle

A rhombus pattern bracelet 3DPrinted with SLS Selective Laser Sintering.

A rhombus pattern bracelet 3DPrinted with SLS Selective Laser Sintering, available in strong and flexible Nylon.

Outer BumpBangle

Inner BumpBangle

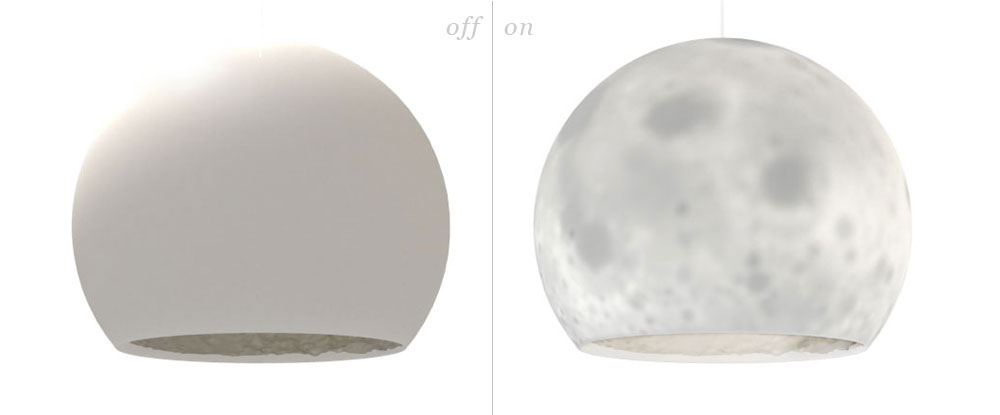

MoonLamp [concept]

The moonLamp explores the translucency proprietress of the 3DPrinted material by wrapping a lunar terrain geometry in the inner wall of the lamp shade.

The moonLamp explores the translucency proprietress of the 3DPrinted material by wrapping a lunar terrain geometry in the inner wall of the lamp shade.

When the lamp is lighted, it displays a Moon landscape on its surface.

The lamp is smooth on the outside, and it appears as a white globe when the light is off.

This work proposes subtle complexity, a quiet approach towards the aesthetics of 3DPrinted goods.

The same design principle can be applied to other lamps by creating an inner wall texture from custom imagery like photos or drawings.

The moonLamp was modeled out of a lunar topographic bump map from Lunar Reconnaissance Orbiter LOLA data, released in 2010.

This lamp was a random idea in 2011.

now is a (kitsch) product made by someone (not me).

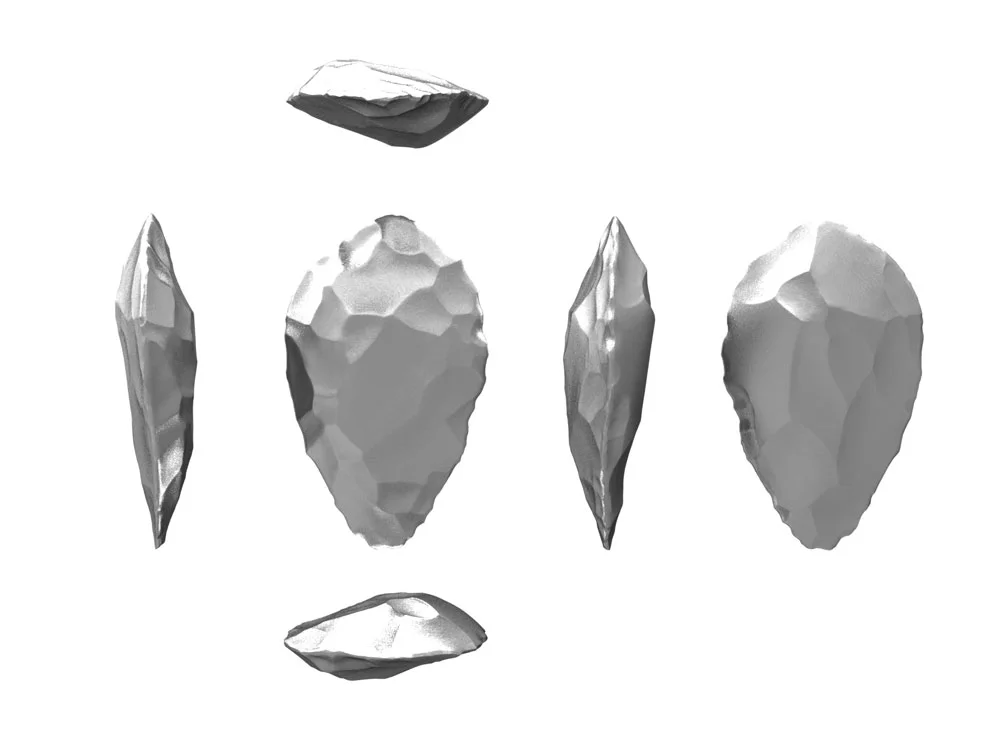

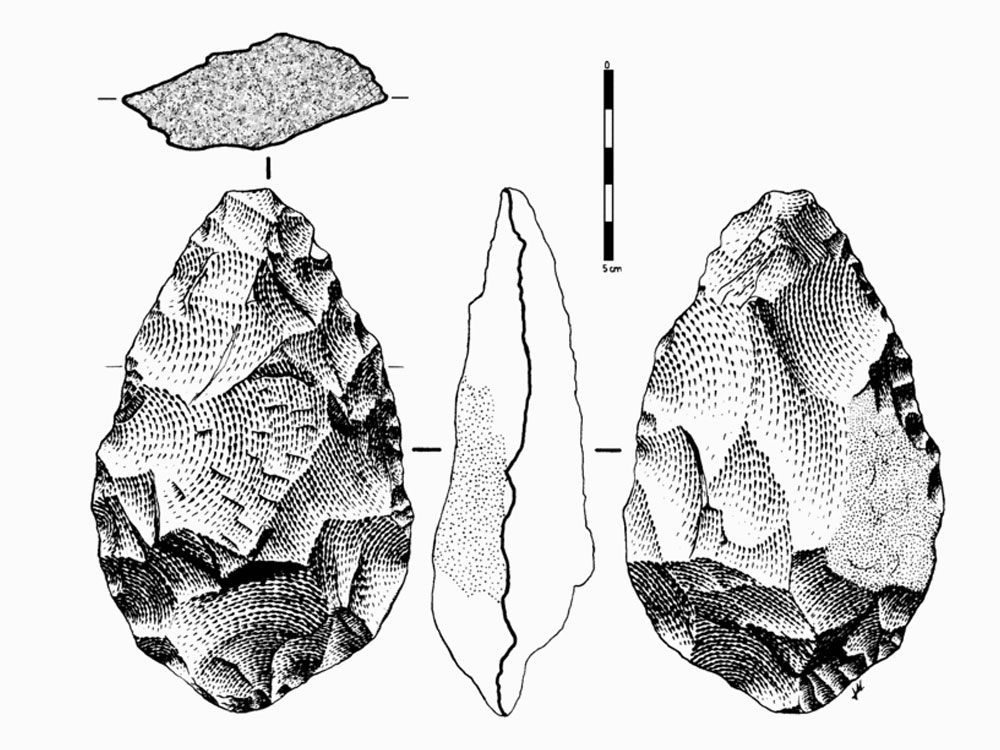

neopaleo

HandAxe, 3D Printed

HandAxe,

3D Printed

Stone Tools were very popular 2 Million years ago, back in the Paleolithic, hominids spent their time shaping stones meticulously to impress the peers on their skillful ability to make useful things.

Now we can do the same, 3DPrint a hand-axe and showcase our technological evolution.

It has been a long time since individuals haven’t been able to produce objects using contemporary technology, during the last centuries, the production means have been capitalized by a few who controlled what was produced, when and how. Digital Fabrication brings the technology of producing things back to the individuals, allowing us to make stuff at our will, how and when we want.

3DPrinting a HandAxe, is the first step towards production independence; you make your tools.

Fully functional hand-axe is modeled from a typical Acheulean stone tool found in Zamora, Spain.